For most manufacturers, 3PL integrations are a tangled web of EDI connections. Learn how to simplify your 3PL integration with Orderful.

What are 3PLs and why do brand manufacturers use them?

Working with a 3PL typically involves seven core EDI transaction types.

This article explores how brand manufacturers can optimize their integrations with 3PLs.

Third-party logistics (3PL) providers offer additional support for specific stages of shipping operations, serving as links in outsourced distribution and fulfillment stages of the supply chain. While 3PL services have always been a significant player in supply chain operations, their involvement continually increases as companies’ sourcing, manufacturing, and customer bases become steadily more multinational.

3PLs can provide warehousing, shipping, and picking and packing solutions—essentially covering any logistics service that brand manufacturers can’t handle. Brand manufacturers tend to engage 3PLs when they outgrow their startup facilities and systems. For example, a startup company that sells makeup out of a garage may start getting a flood of orders on its eCommerce website. Suddenly, its manual processes can no longer keep up with customer needs. Rather than buying its own warehouse and fleet of trucks, the startup might engage a 3PL to handle some or all of its warehousing, packing, and shipping in multiple states.

The complexity of 3PL integration

For most brand manufacturers, 3PL integrations are a tangled web of EDI connections. But they don’t have to be.

To build successful relationships, brand manufacturers and 3PL providers must establish dynamic connections for shared visibility of real-time data flows. This is why your 3PL must be integrated with the EDI system.

When executed correctly, 3PL EDI integration optimizes efficiency through enhanced visibility and the automation of retail order fulfillment. Brand manufacturers can also connect with an expanded range of companies and trading partners, enabling them to deliver more products to more consumers in the long run.

If a brand manufacturer works with several 3PLs, it weighs heavily on them to build and maintain multiple custom integration environments. With legacy EDI systems, they’re creating point-to-point integrations for all transaction types, for each 3PL. In some cases, there will be a need for integrating with fourth- and fifth-party logistics systems, furthering the convolution.

The trick to simplifying this muddled system is to set up transactions as efficiently as possible using a centralized EDI core rather than point-to-point integration.

Click here to skip ahead to learn solutions for streamlining 3PL integration with EDI.

Why 3PL integration is so difficult

The main reason 3PL integration is typically hard to set up is that there’s very little standardization between 3PLs and their customers. There ‘s usually a leader and a follower in any EDI relationship. The leader dictates how the EDI transactions must be formatted. If the 3PL company doesn’t act as a leader, the brand manufacturer must do so, even if they’re not used to doing that. What follows is ongoing confusion about the integration requirements between the two parties.

Some 3PLs will run a brand manufacturer’s warehousing software in their own warehouse. In other words, they’ll log onto the software and pick-and-pack in the brand manufacturer’s system. This may sound like a good arrangement because it eliminates the need for integration—but it’s not a scalable approach. If the 3PL is doing this for 10 different companies, there’s no way they will learn the nuances of each company’s system. Thus, the whole process becomes highly error-prone.

Other 3PLs will try to integrate data with a brand manufacturer. But most 3PLs are small companies that lack the IT headcount and expertise to onboard new brand manufacturers properly. This results in much back-and-forth with the brand manufacturer as both parties try to figure out who’s responsible for requirements and test the configurations they’ve set up.

Regardless of which approach they take, 3PLs are incentivized to make their processes as easy as possible for brand manufacturers. So they do—but they don’t follow any standards in the process. Some 3PLs will accept any data format a manufacturer sends them, which forces them to create custom integrations for each company. By being so flexible with brand manufacturers, 3PLs actually create extra work for themselves because no integration can be reused across relationships. Some 3PLs have tried to get around this problem by introducing their own APIs—but again, many 3PLs are small companies that lack the technical expertise for such ambitious ventures.

What transaction types you need

To establish a new EDI integration, a brand manufacturer needs to configure the specific set of transactions that they and their 3PL partner will be using with each other. These transaction types may be different from the types used in wholesale transactions.

Working with a 3PL normally involves seven core EDI transactions types. Here’s a step-by-step breakdown to help you understand these transactions.

- 856 – Ship Notice Manifest. The 856 Ship Notice Manifest, triggered by the supplier, notifies the customer that the shipment is on its way and allows both parties to track its progress in their TMS systems. It also serves as a pre-receipt to assist the customer in their receiving operations.

- 943 – Warehouse Stock Transfer Shipment Advice. The 943 Warehouse Stock Transfer Shipment Advice is the EDI document that brand manufacturers and distributors use to tell third-party or remote warehouses that products are being sent to their location. It includes detailed information about the specific items.

- 944 – Warehouse Stock Transfer Receipt Advice. The 944 Warehouse Stock Transfer Receipt Advice is used by a receiving location to advise the depositor or its agent that a transfer shipment has been received. It includes detailed information about the product that has been received in the 3PL warehouse system.

- 940 – Warehouse Shipping Order. The 940 Warehouse Shipping Order is the EDI transaction sent by the brand manufacturer to third-party logistics providers (3PLs) to formally request the shipment of goods from a specified warehouse to a buyer’s location.

- 945 – Warehouse Shipping Advice. The 945 Warehouse Shipping Advice is sent from a 3PL provider or remote warehouse to notify them that a shipment has taken place.

- 850 – Purchase Order. The 850 Purchase Order is an electronic purchase order sent from a buyer to a seller, serving as a formal order for goods or services.

- 810 – Invoice. The 810 Invoice is the electronic version of a paper-based invoice, sent in response to an 850 Purchase Order, serving as a request for payment once goods have shipped or services have been provided.

For more information, read our article about Transportation EDI Transactions or What EDI Transactions Do Your Trading Partners Require.

How do these EDI transaction types usually interact with one another?

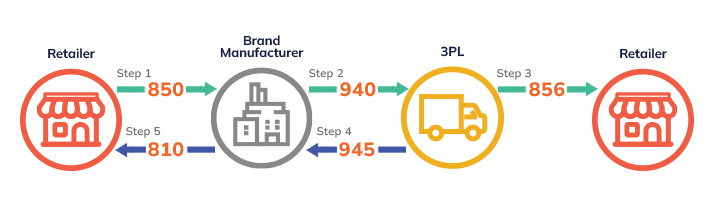

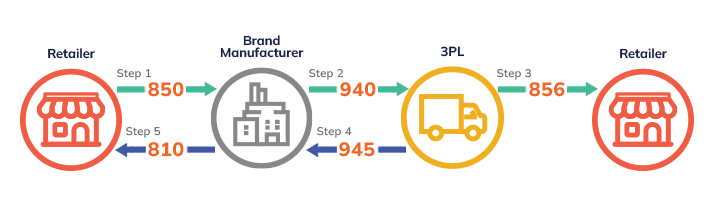

Suppose you’re a brand manufacturer taking orders from a retailer. Your website will pass orders into your ERP, or system of record, which will then communicate via EDI with your 3PL provider’s system so that the order can be sent to the retailer. Below is a step by step process of how the EDI transactions flow:

Step 1: The transaction begins when a retailer sends you an 850 (purchase order).

Step 2: You now need to fulfill the order. You must pick-and-pack from your facility or pick-and-pack from a 3PL. If using a 3PL, you will send a 940 (warehouse shipping order) to your 3PL asking for the order to be fulfilled.

Step 3: Once your 3PL fulfills the order, they send an 856 (ship notice manifest) on your behalf to the retailer indicating that the shipment has left the warehouse.

Step 4: They then communicate back to you via a 945 (warehouse shipping advice) that the shipment has left the warehouse. The 945 can include information like the shipment identification, item, quantity, where it’s shipping, the transportation method, and shipping service level.

Step 5: Step 5: Once you receive the 945, you can invoice the retailer with an 810 (invoice) because you have confirmation that the product has been shipped.

943 and 944 Stock Transfer Transactions

How do the 943 (warehouse stock transfer shipment advice) and 944 (warehouse stock transfer receipt advice) transactions fit into a 3PL EDI integration?

To meet customer demands, brand manufacturers need to ensure that their 3PL is stocked with product.

Step 1: A brand manufacturer sends a 943 to their 3PL to let them know goods are coming into their warehouse and when the product will be delivered.

.png&w=1080&q=75)

Step 2: Once the 3PL receives the product, it will send the brand manufacturer a 944 to notify them that the product was received. The 944 serves as a receipt of the order and includes any adjustments that need to be made to the original 943 due to potentially damaged or missing products.

.png&w=1080&q=75)

How to manage your 3PL EDI integrations with maximum efficiency

Common problems that companies face usually come from the complexity of the 3PL logistics process itself, combined with outdated EDI integration challenges with both new and existing trading partners. Heavy reliance upon antiquated forms of communication rather than automation slows essential information exchanges, leading to frustration between companies. Additionally, failure to create a foundational EDI system that can scale as your business grows will cause unnecessary work for various teams.

You can make it easier to manage 3PL integrations by implementing an EDI system to help the process and then choosing one party to be the leader. Typically, it should be the 3PL vendor because their business stays the same as they work with many different brand manufacturers. The 3PL should stipulate their requirements clearly and let the brand manufacturers build the integrations needed to meet these requirements.

When you implement a cloud EDI solution such as Orderful, your 3PL can simply publish their requirements in the system. From there, brand manufacturers can work towards the requirements using self-service tools. And both the 3PL and the retailer will have access to an API if they need it.

With Orderful, you can:

- Consolidate EDI integrations. Leveraging a provided canonical API, you can minimize the number of individual integrations by 90% compared to point-to-point practices.

- Leverage a platform with flourishing networks of preconnected trading partners. For example, Orderful’s ecosystem of preconnected companies evolves with each new user. This codifies the partners and arms you with specific guidelines, letting you skip ahead to EDI data validation. Our network includes a full spectrum of businesses, from transportation to warehouses to retailers.

- Onboard all new connections quickly. Members of your supply chain that are not currently part of the Orderful network can quickly join to eliminate delays. You and your 3PL provider can choose from multiple pre-configured code settings, such as 12XG or JSON. What’s more, the Orderful team will personally assist with all onboarding, free of charge.

Orderful: the ultimate EDI solution for 3PL integration

Most brand manufacturers working with legacy EDI systems have built custom integration environments maintained by an in-house team of EDI experts or have outsourced to a managed service provider. Regardless, this web of integrations is complicated and expensive to maintain. On top of that, it’s challenging to scale as you continue to grow your business.

When you integrate with Orderful, you don’t have to build point-to-point integrations. Orderful is a central point of integration for your ERP, or system of record, and your 3PL. Connect once to our platform and tap into an existing network of 3PLs and partners, consolidating all of your EDI vendors into one hub.

Speak with one of our EDI experts to learn more.

_Integrations_Using_EDI_Software1.avif&w=2048&q=75)